AWG seris copper tube terminal lugs

Description

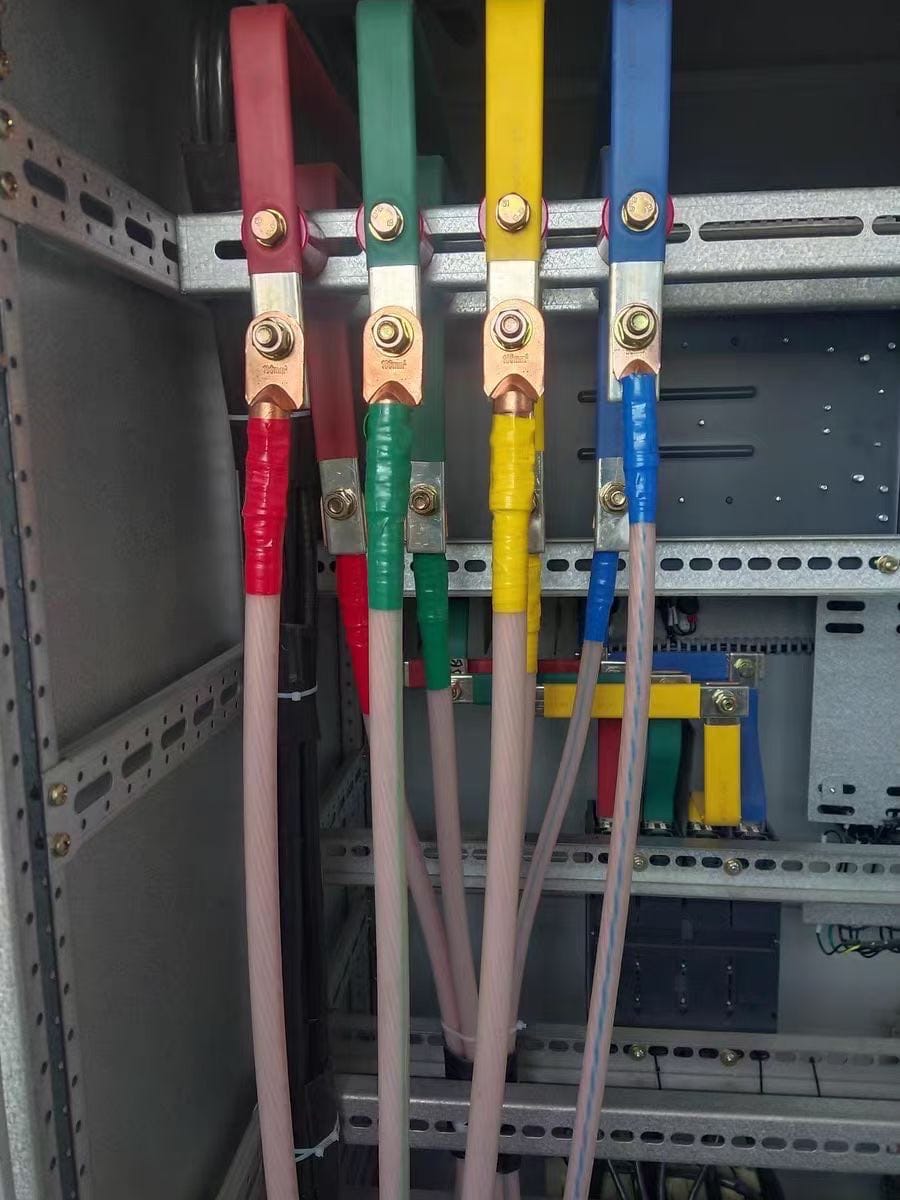

LILIAN copper lugs made by T2 pure copper rod with good electrical performance, resistance to galvanic corrosion, and long service life, they are suitable for connection the copper cable to other electrical equipment, like distribution terminal block,fuse terminal block,solar panels,home applications,etc., .Terminal lugs can be crimped by hydraulic cable lugs crimper tool or hammer style crimper.Our terminal lugs with heavy duty construction improves high temperature durability and closed design seals out the moisture, ensure connection reliability.The ends with high standard flared opening for wire insert more easier.

Material

Copper cable lugs are made of 99.9% pure copper rod with tinned coating for corrosion protection

Working temperature: -55°C ~ 150°C.

Cable lugs type: copper cable lug,copper tinned cable lug,aluminum cable lug,bimetallic lugs,mechanical connectors and lugs.

c

|

ITEM NO. |

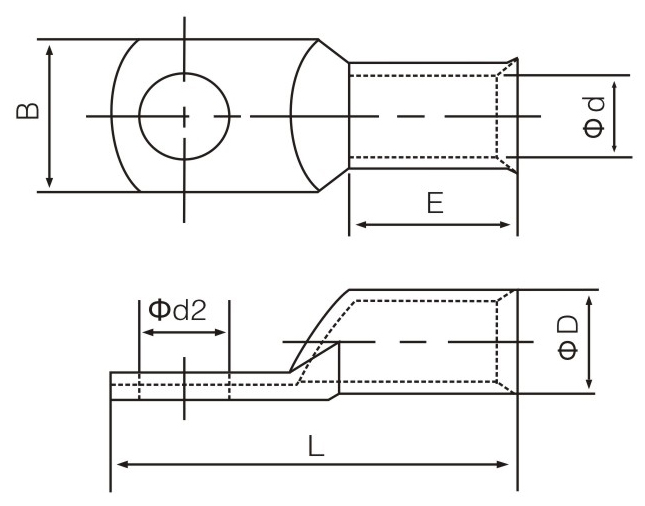

Dimension(mm) |

|||||

|

Φd2 |

B |

L |

ΦD |

Φd |

E |

|

|

8#10 |

5.1 |

11.8 |

33.3 |

7.1 |

4.8 |

13 |

|

8*1/4 |

6.8 |

11.8 |

33.3 |

|||

|

8*5/16 |

8.3 |

11.8 |

33.3 |

|||

|

8*3/8 |

10.4 |

14.5 |

33.3 |

|||

|

8*1/2 |

13.1 |

17 |

33.3 |

|||

|

6#10 |

5.1 |

11.8 |

37.3 |

8.1 |

5.9 |

15 |

|

6*1/4 |

6.8 |

13.7 |

37.3 |

|||

|

6*5/16 |

8.3 |

13.7 |

37.3 |

|||

|

6*3/8 |

10.4 |

13.7 |

37.3 |

|||

|

6*1/2 |

13.1 |

17 |

37.3 |

|||

|

4*1/4 |

6.8 |

13.8 |

38.9 |

9.5 |

7.3 |

15.5 |

|

4*5/16 |

8.3 |

13.8 |

38.9 |

|||

|

4*3/8 |

10.4 |

14.5 |

38.9 |

|||

|

4*1/2 |

13.1 |

17 |

38.9 |

15 |

||

|

2*1/4 |

6.8 |

16.5 |

41.1 |

11.1 |

8.5 |

16 |

|

2*5/16 |

8.3 |

16.5 |

41.1 |

|||

|

2*3/8 |

10.4 |

16.5 |

41.1 |

|||

|

2*1/2 |

13.1 |

17 |

41.1 |

15.3 |

||

|

1*1/4 |

6.8 |

16.4 |

43.6 |

11.7 |

9.1 |

16 |

|

1*5/16 |

8.3 |

16.4 |

43.6 |

|||

|

1*3/8 |

10.4 |

17.1 |

43.6 |

|||

|

1*1/2 |

13.1 |

19.1 |

43.6 |

|||

|

1/0*1/4 |

6.8 |

18.4 |

46.8 |

13 |

10.4 |

19 |

|

1/0*5/16 |

8.3 |

18.4 |

46.8 |

|||

|

1/0*3/8 |

10.4 |

18.4 |

46.8 |

|||

|

1/0*1/2 |

13.1 |

21 |

46.8 |

|||

|

2/0*1/4 |

6.8 |

21 |

52.4 |

14.2 |

11.7 |

22 |

|

2/0*5/16 |

8.3 |

21 |

52.4 |

|||

|

2/0*3/8 |

10.4 |

21 |

52.4 |

|||

|

2/0*1/2 |

13.1 |

21 |

52.4 |

21 |

||

|

3/0*5/16 |

8.3 |

23.1 |

55.9 |

15.7 |

13 |

22.5 |

|

3/0 |

10.4 |

23.1 |

55.9 |

|||

|

3/0*1/2 |

13.1 |

23.1 |

55.9 |

|||

|

4/0*5/16 |

8.3 |

25.8 |

60.5 |

17.2 |

14.2 |

24 |

|

4/0*3/8 |

10.4 |

25.8 |

60.5 |

|||

|

4/0*1/2 |

13.1 |

25.8 |

60.5 |

|||

lnstallation Precautions

1.The screw must be tightened.

2.The cable and copper lug must be inserted in place and pressed with crimping tools.