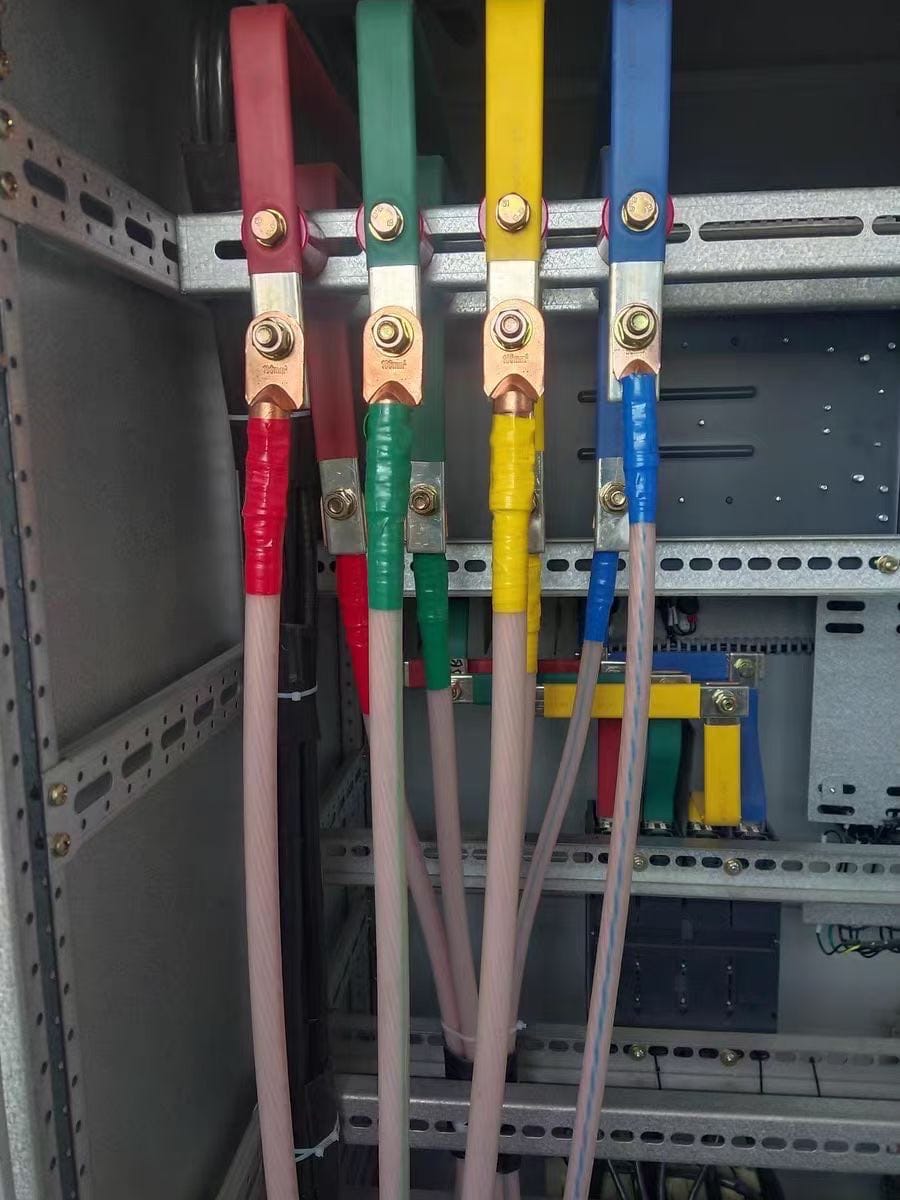

DIN 46234

Material

Copper cable lugs are made of 99.9% pure copper rod with tinned coating for corrosion protection

Working temperature: -55°C ~ 150°C.

Cable lugs type: copper cable lug,copper tinned cable lug,aluminum cable lug,bimetallic lugs,mechanical connectors and lugs.

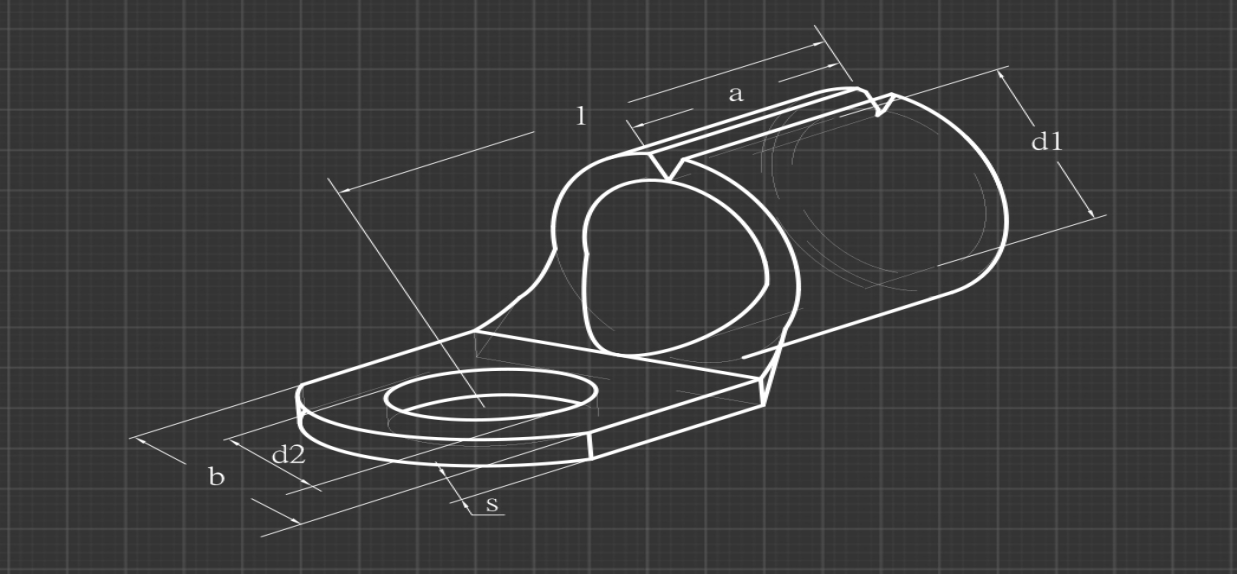

| Conductor | Bolt | d1 | d2 | b | a | s | L | Section |

|

A2.5-1 |

0.5-1 |

M2.5 |

1.6 |

2.8 |

6 |

5 |

0.8 |

14 |

|

A3-1 |

0.5-1 |

M3 |

1.6 |

3.2 |

6 |

5 |

0.8 |

14 |

|

A3.5-1 |

0.5-1 |

M3.5 |

1.6 |

3.7 |

6 |

5 |

0.8 |

14 |

|

A4-1 |

0.5-1 |

M4 |

1.6 |

4.3 |

8 |

5 |

0.8 |

16 |

|

A5-1 |

0.5-1 |

M5 |

1.6 |

5.3 |

10 |

5 |

0.8 |

18 |

|

A6-1 |

0.5-1 |

M6 |

1.6 |

6.5 |

11 |

5 |

0.8 |

20.5 |

|

A8-1 |

0.5-1 |

M8 |

1.6 |

8.4 |

14 |

5 |

0.8 |

23 |

|

A10-1 |

0.5-1 |

M10 |

1.6 |

10.5 |

18 |

5 |

0.8 |

28 |

|

A3-2.5 |

1.5-2.5 |

M2.5 |

2.3 |

3.2 |

6 |

5 |

0.8 |

14 |

|

A3.5-2.5 |

1.5-2.5 |

M3 |

2.3 |

3.7 |

6 |

5 |

0.8 |

14 |

|

A4-2.5 |

1.5-2.5 |

M4 |

2.3 |

4.3 |

8 |

5 |

0.8 |

16 |

|

A5-2.5 |

1.5-2.5 |

M5 |

2.3 |

5.3 |

10 |

5 |

0.8 |

19 |

|

A6-2.5 |

1.5-2.5 |

M6 |

2.3 |

6.5 |

11 |

5 |

0.8 |

21.5 |

|

A8-2.5 |

1.5-2.5 |

M8 |

2.3 |

8.4 |

14 |

5 |

0.8 |

24 |

|

A10-2.5 |

1.5-2.5 |

M10 |

2.3 |

10.5 |

15 |

5 |

0.8 |

29 |

|

A12-2.5 |

1.5-2.5 |

M12 |

2.3 |

13 |

18 |

5 |

0.8 |

29 |

|

A4-6 |

4-6 |

M4 |

3.6 |

4.3 |

8 |

6 |

1.0 |

18 |

|

A5-6 |

4-6 |

M5 |

3.6 |

5.3 |

10 |

6 |

1.0 |

20 |

|

A6-6 |

4-6 |

M6 |

3.6 |

6.5 |

11 |

6 |

1.0 |

21.5 |

|

A8-6 |

4-6 |

M8 |

3.6 |

8.4 |

14 |

6 |

1.0 |

26 |

|

A10-6 |

4-6 |

M10 |

3.6 |

10.5 |

18 |

6 |

1.0 |

30 |

|

A12-6 |

4-6 |

M12 |

3.6 |

13 |

18 |

6 |

1.0 |

30 |

|

A5-10 |

10 |

M5 |

4.5 |

5.3 |

10 |

8 |

1.1 |

21 |

|

A6-10 |

10 |

M6 |

4.5 |

6.5 |

11 |

8 |

1.1 |

22.5 |

|

A8-10 |

10 |

M8 |

4.5 |

8.4 |

14 |

8 |

1.1 |

27 |

|

A10-10 |

10 |

M10 |

4.5 |

10.5 |

18 |

8 |

1.1 |

30 |

|

A12-10 |

10 |

M12 |

4.5 |

13 |

22 |

8 |

1.1 |

34 |

|

A5-16 |

16 |

M5 |

5.8 |

5.3 |

11 |

10 |

1.2 |

25.5 |

|

A6-16 |

16 |

M6 |

5.8 |

6.5 |

11 |

10 |

1.2 |

25.5 |

|

A8-16 |

16 |

M8 |

5.8 |

8.4 |

14 |

10 |

1.2 |

29 |

|

A10-16 |

16 |

M10 |

5.8 |

10.5 |

18 |

10 |

1.2 |

33 |

|

A12-16 |

16 |

M12 |

5.8 |

13 |

22 |

10 |

1.2 |

37 |

|

A5-25 |

25 |

M5 |

7.5 |

5.3 |

12 |

11 |

1.5 |

31 |

|

A6-25 |

25 |

M6 |

7.5 |

6.5 |

12 |

11 |

1.5 |

31 |

|

A8-25 |

25 |

M8 |

7.5 |

8.4 |

16 |

11 |

1.5 |

33 |

|

A10-25 |

25 |

M10 |

7.5 |

10.5 |

18 |

11 |

1.5 |

36 |

|

A12-25 |

25 |

M12 |

7.5 |

13 |

22 |

11 |

1.5 |

42 |

|

A16-25 |

25 |

M16 |

7.5 |

17 |

28 |

11 |

1.5 |

48 |

|

A6-35 |

35 |

M6 |

9 |

6.5 |

15 |

12 |

1.6 |

33.5 |

|

A8-35 |

35 |

M8 |

9 |

8.4 |

16 |

12 |

1.6 |

34 |

|

A10-35 |

35 |

M10 |

9 |

10.5 |

18 |

12 |

1.6 |

36 |

|

A12-35 |

35 |

M12 |

9 |

13 |

22 |

12 |

1.6 |

42 |

|

A16-35 |

35 |

M16 |

9 |

17 |

28 |

12 |

1.6 |

50 |

|

A6-50 |

50 |

M6 |

11 |

6.5 |

18 |

16 |

1.8 |

43 |

|

A8-50 |

50 |

M8 |

11 |

8.4 |

18 |

16 |

1.8 |

43 |

|

A10-50 |

50 |

M10 |

11 |

10.5 |

18 |

16 |

1.8 |

43 |

|

A12-50 |

50 |

M12 |

11 |

13 |

22 |

16 |

1.8 |

47 |

|

A16-50 |

50 |

M16 |

11 |

17 |

28 |

16 |

1.8 |

54 |

|

A6-70 |

70 |

M6 |

13 |

6.5 |

22 |

18 |

2.0 |

48 |

|

A8-70 |

70 |

M8 |

13 |

8.4 |

22 |

18 |

2.0 |

48 |

|

A10-70 |

70 |

M10 |

13 |

10.5 |

22 |

18 |

2.0 |

48 |

|

A12-70 |

70 |

M12 |

13 |

13 |

22 |

18 |

2.0 |

48 |

|

A16-70 |

70 |

M16 |

13 |

17 |

28 |

18 |

2.0 |

56 |

|

A8-95 |

95 |

M8 |

15 |

8.4 |

24 |

20 |

2.5 |

54 |

|

A10-95 |

95 |

M10 |

15 |

10.5 |

24 |

20 |

2.5 |

54 |

|

A12-95 |

95 |

M12 |

15 |

13 |

24 |

20 |

2.5 |

54 |

|

A16-95 |

95 |

M16 |

15 |

17 |

28 |

20 |

2.5 |

58 |

|

A8-120 |

120 |

M8 |

17 |

8.4 |

24 |

22 |

3.0 |

56 |

|

A10-120 |

120 |

M10 |

17 |

10.5 |

24 |

22 |

3.0 |

56 |

|

A12-120 |

120 |

M12 |

17 |

13 |

24 |

22 |

3.0 |

56 |

|

A16-120 |

120 |

M16 |

17 |

17 |

28 |

22 |

3.0 |

62 |

|

A10-150 |

150 |

M10 |

19 |

10.5 |

30 |

24 |

3.2 |

65 |

|

A12-150 |

150 |

M12 |

19 |

13 |

30 |

24 |

3.2 |

65 |

|

A16-150 |

150 |

M16 |

19 |

17 |

30 |

24 |

3.2 |

65 |

|

A12-185 |

185 |

M12 |

21 |

13 |

36 |

28 |

3.5 |

68 |

|

A16-185 |

185 |

M16 |

21 |

17 |

36 |

28 |

3.5 |

68 |

|

A12-240 |

240 |

M12 |

23.5 |

13 |

38 |

32 |

4.0 |

75 |

|

A16-240 |

240 |

M16 |

23.5 |

17 |

38 |

32 |

4.0 |

75 |

lnstallation Precautions

1.The screw must be tightened.

2.The cable and copper lug must be inserted in place and pressed with crimping tools.